R & D Background

Overview

Why are luminescent signs necessary?

- Roads are becoming faster and more complicated, but the driver’s perception, judgment, and actions are limited.

- As the technology and equipment (virtual information) develop, the driver’s perception of the actual road information becomes insufficient.

- Road environment, the driver, and social and weather conditions such as aging, gender, night time driving, distracted driving, weather deterioration, and etc. are deteriorating.

At nighttime and after bad weather, luminescent signs that a driver with poor sight can clearly perceive become necessary.

Requirements for Luminescent Signs

- Must transmit the sign information clearly from a distance regardless of weather conditions.

- Should not cause visual disturbance or cognitive error such as dazzling, blurring, or missing texts.

- Must be easy to install, durable and easy to maintain on site.

Key Issues in Designing Luminescent Signs

- Exposure of the surface of light source signboard (direct luminescence of cover information) or direct attachment of frame must be avoided.

- LED usage must be minimized.

- A combination of simple and optimized components is necessary.

What key technologies should be implemented into the product to meet the requirements?

Low power drive

Make the installation easy

(Resolve the electricity intake problem)

Luminescence quality

Signs discrimination / attraction / visibility / readability acquisition / solution for dazzling and light smearing

Durability / Stability

Maintain long-term function without maintenance and provide information without distortion

Maintainability

Solutions for pre-maintenance risk of accidents, excessive costs, and absence of signs during temporary demolitions

Design Issues

Problems in Designing Luminescent Type Signs – Durability / Stability / Maintainability

Key Challenges

- Separate LEDs from the frame

- Reduce LEDs being used

- Simple Assembly of components

Purpose

- Protect LED devices from external environment

- Enable low power consumption by electrical protection of LEDs

- Improve durability / stability and obtain maintainability

Directions for realizations

- Avoid exposure of signboard surface of light source and direct frame attachment

- LED usage should be minimized while satisfying proper light emission performance

- Simplified, optimized combination of parts

- Separate LEDs from the Frame

Separate LEDs from the Frame

– Avoid exposure of signboard surface of light source or direct frame attachment

- Damage is caused by radiant heat, especially when exposed to direct sunlight.

- Stiffening of protective film (lens) on the surface of LEDs by ultraviolet ray → Reduced light transmittance

-

Sign information distortions / omissions due to partial LED failure

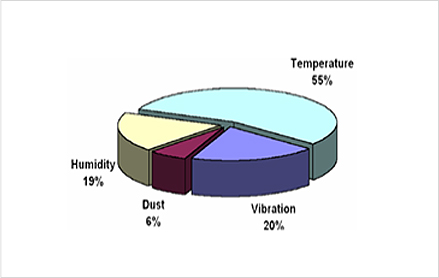

[Figure 1] Causes for the failure of LEDs

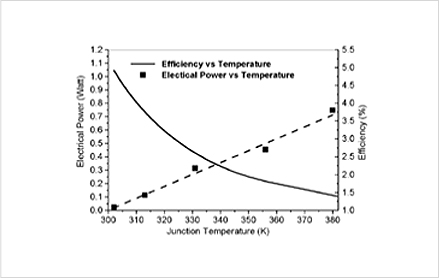

[Figure 2] Temperature-dependent LED package efficiency

Reduce LEDs being used

– Reduce LEDs being used

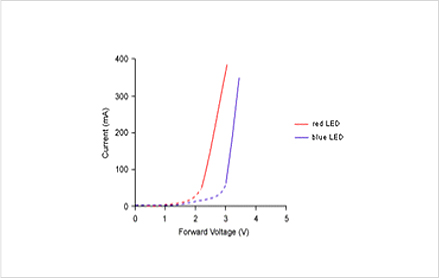

- LEDs are characterized by a sudden increase in current consumption from a small voltage rise.

- When the number of focused LEDs increases, a considerable amount of heat is generated

- Rise in junction temperature due to overcurrent and heat reduce luminous flux and life span of LEDs.

- Failure of some LEDs in a parallel array spread to adjacent LEDs in the same wiring.

Relationship between DC voltage and current of LEDs

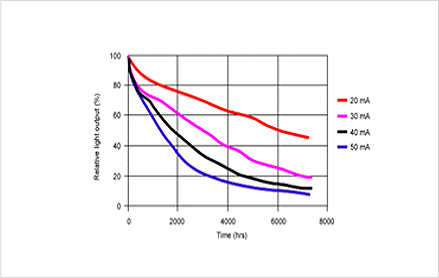

* Luminous flux retention rate (effective life of device) drop sharply

when current consumption increases

Relationship between overloaded PHOSPHOR LED for white signal and luminous flux retention

Simple Assembly

– Combination of optimized parts

- Installation of replacement signs is difficult in reality when separated from the pillar for maintenance.

- If the light source is not separated from the body frame part, the whole sign should be dismantled in case of failure.

- Road situations that are difficult to control and dangerous require parts for maintenance to be gathered in the inspection window.

Key Requirements

Politic effects of signs

Deliver a clear and consistent sign

- Traffic safety signs should clearly inform the driver of information related to regulations, instructions and attentions, so that the driver himself / herself can faithfully implement deceleration, steering, and driving.

High standard for quality and dignity of signs

- Unlike general signs, the nighttime luminescent type signs determine the meaning of the sign that the actual drivers perceive and the degree of trust and respect of the driver for the sign information according to the emission quality.

Minimization of adverse effects due to electro-luminescence

- It is necessary to maximize politic effects holistically by thoroughly blocking all the dysfunctions related to luminescence.

GOOD

BAD

Driver’s perception

Driver’s perception

- There are various types of signs in the current road conditions, but differentiating characteristics that can determine the priority according to the importance of the sign information are not expressed.

- As commercial signs (LED signboards or internal illuminated signs) that are brighter than signs grow in number, the attractions of signs that provide important information for drivers are decreased.

- Some of the light emitting type signs (LED cover or interior light) are expressed in the same manner with surrounding commercial signs, so the discriminatory power is insufficient to gain attention from the driver.

- It is necessary to have a luminescence technology with clear discrimination and attention that is distinct from signboards.

Sufficient sign visibility and pattern readability

- As the light emission angle increases, blurring increases. Therefore, visibility and readability are continuously decreased with increasing distance, and the restrictions from whiteouts due to light scattering of fogs increase.

- The enhancement of visibility and readability is the most important requirement for signs because it enables drivers to make appropriate judgments and vehicle maneuvers by providing adequate visibility and read distances.

- As the light emission angle increases, blurring increases. Therefore, visibility and readability are continuously decreased with increasing distance, and the restrictions from whiteouts due to light scattering of fogs increase.

Suppression of disturbance of driving vision by excessive stimulation (dazzling)

- Since signs must allow the driver to read the information for a sufficient amount of time to be able to interpret and make appropriate judgments, a reliable visual information delivery is the most important for drivers.

- Dazzling caused by excessive illumination and brightness is the most typical problem that obstructs the vision of the driver in the night. Drivers experience temporary loss of vision by positive afterimage or they look away from signs.

- For example, LED signboards emit powerful light from each LEDs direct emission from the surface and cause intense dazzling, while the internal illumination method causes temporary deterioration of the driving vision due to positive afterimage in case of full emission of the surface of the signboard.

Installation and management

Ease of installation

- Underground burial, which is a standard for road facilities, is a high-cost construction. Highly dangerous roads are usually in remote places where electrical input is impossible.

- Additional work and costs are incurred in the maintenance of the power distribution network and electricity bills even after the electricity is implemented.

- Driving by solar power is the only solution, and the technical requirements for extremely low-power lighting must be implemented when considering the number operational days.

Durability and stability

- Signs require strong durability that can be operated without any special failure for long periods of time even when exposed to harsh road environments. (UV, heat, moisture, vibration, wind, dust)

- Stable operation without malfunction due to a change in temperature, unnecessary blinking, partial breakage of the light emitting elements, or deterioration in performance that reduce visibility and readability is necessary.

- Because the light emitting type sign is expensive, it needs to have a long-term durability for at least 5 to 10 years, so that it can acquire economical efficiency for investment.

- Durability and stability are degraded when the LED usage is high, the LEDs are exposed, the frame is directly attached, the electricity consumption is high, and when the internal wiring network is complicated.

- LED signboards and interior lighting are dedicated to commercial sign manufacturing technology and have limited ability to meet the durability and reliability requirements of road traffic signs.

Ease of maintenance and measures for failures

- Electrical failure and periodic LED light source replacement are essential to electrical illumination, so the product must be quick and easy to maintain when failure occurs.

- In order to minimize the difficulty working on roads, prevent accidents, and to prevent the absence of the signs due to removal for maintenance purpose, the product must be fixable on site.

- Numerous light sources, sign exposure, direct frame attachment, and complicated structure and wiring cause difficulty for on site fixing, so the product must have minimized and isolated light source and be easy to assemble.

- In case of failure, the retro-reflective function should be maintained. LED signboards are blank-out in case of failure or power outage, so they are unfit for signs other than VMS.